Experienced Thermal Pour & Debridge Company

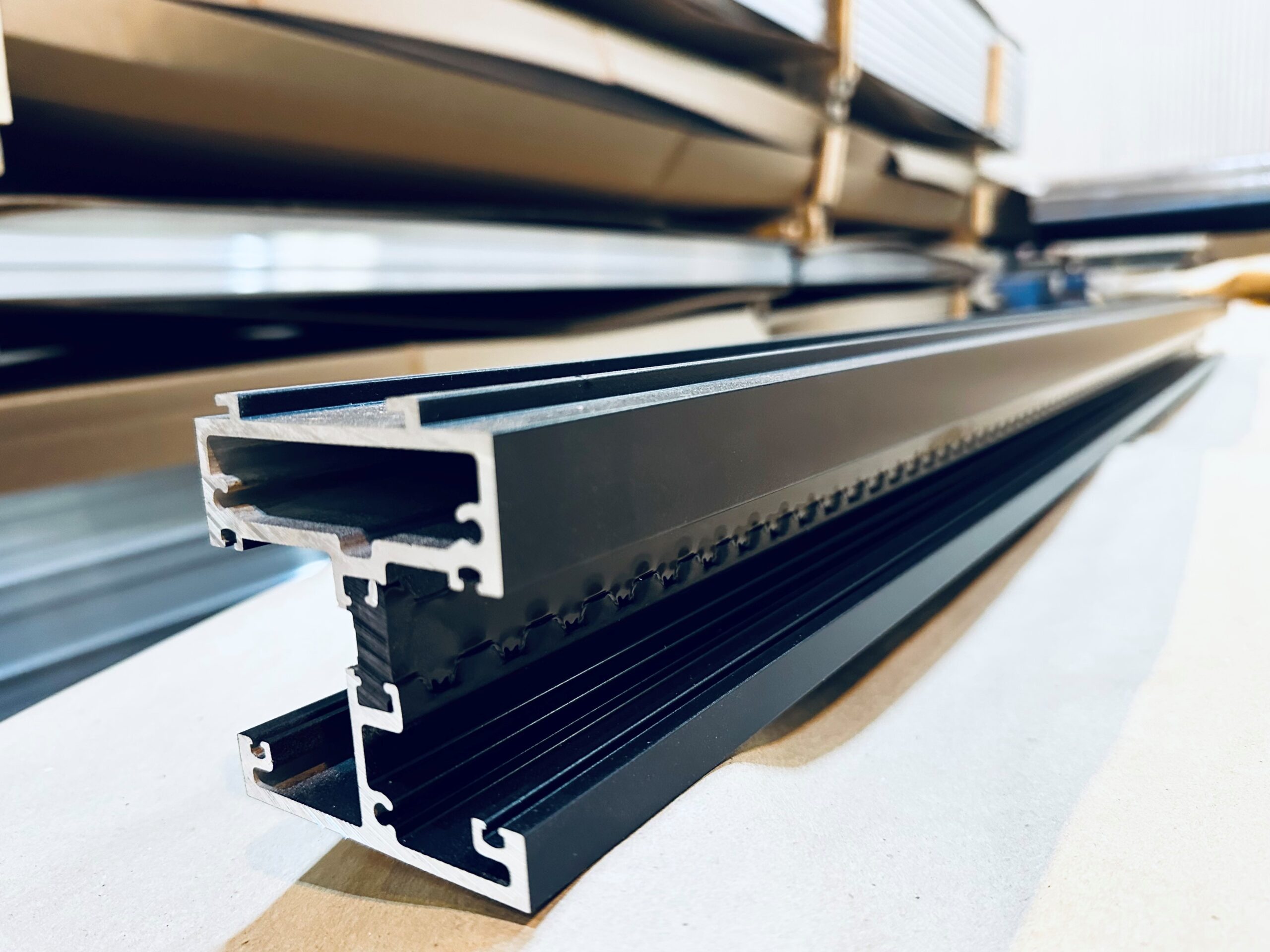

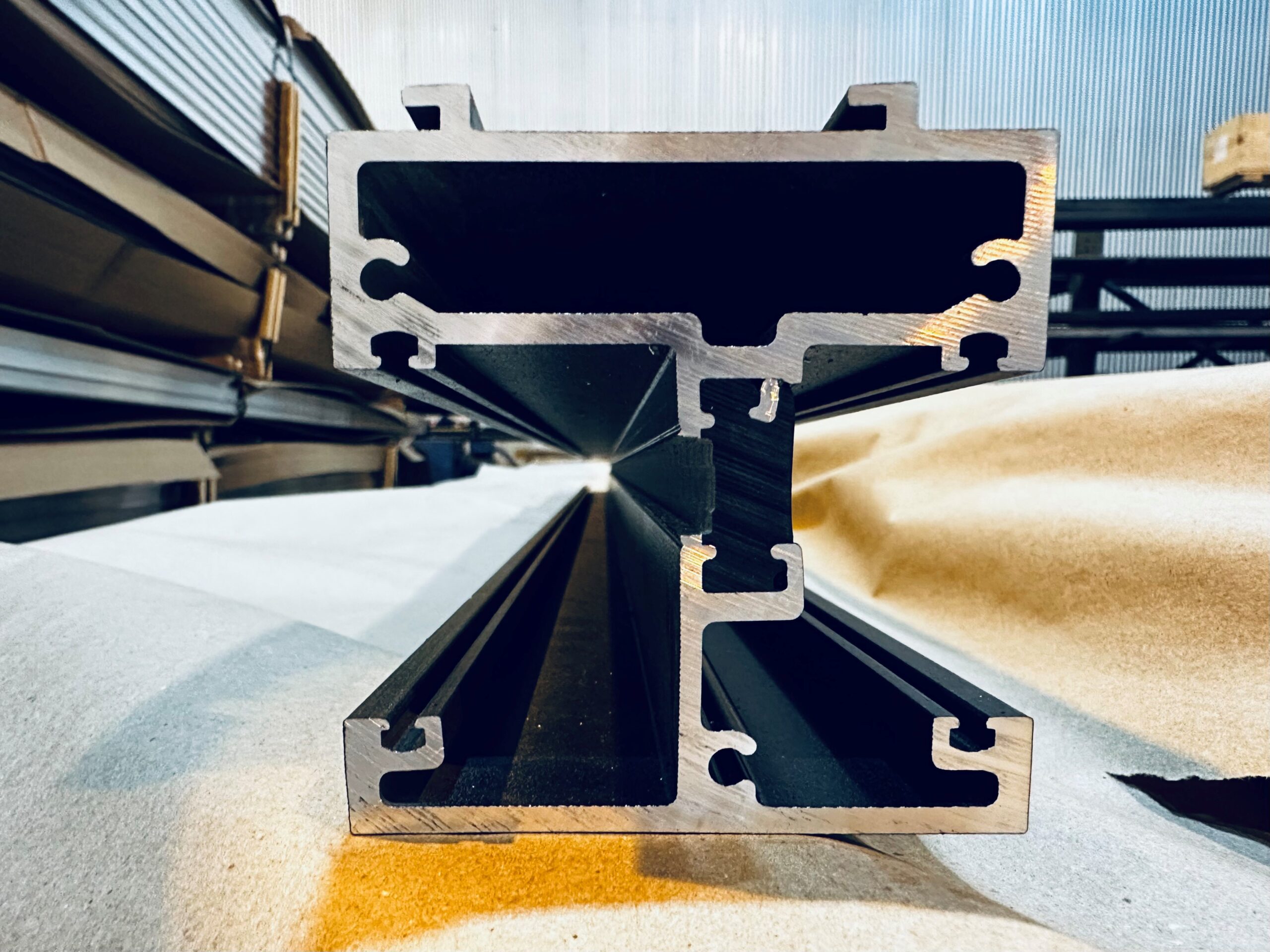

Aluminum extrusions destined for use in windows, doors, and other architectural applications require the experience of a knowledgeable thermal pour and debridge company to achieve the desired thermal insulating properties. This layer of cured polymer, poured into a small channel in the extrusion, helps to prevent unwanted heat transfer that can lead to drafts, rising heating and cooling costs, and condensation. For OEMs and other manufacturers relying on aluminum extrusions, finding a reliable thermal pour and debridge company can be a challenge, especially when the extrusions need additional services like powder coating, machining, or assembly.

That said, RFQUSA recommends Precision Steel Services from Farrell, PA, as a premium thermal pour and debridge company with an extensive array of value-added services like in-house powder coating, welding, machining, and assembly services. Learn more about Precision Steel’s successes working with aluminum extrusions, or visit their RFQUSA profile today to learn more and request a quote!

Learn More About Precision Steel Services

Precision Steel Services: Pouring & Debridging Experts

Precision Steel Services is a premier sheet metal and extrusion fabricating company operating out of Farrell, PA, with almost three full decades of experience. Well known for their thermal pouring and debridging capabilities, the team at Precision Steel currently works with manufacturers in the architectural, commercial construction, and refrigeration industries to provide high-performance extrusions destined for challenging environments. While other pouring and debridging companies may be able to provide similar services to customers in these sectors, few are certified applicators of the industry-leading Azon Thermal Barrier Polymer.

Certified Applicator of Azon Thermal Barrier Polymer

Azon is a world leader in the production of energy-saving thermal barrier technologies that help end users meet the highest standards for energy efficiency and reliable performance. Precision Steel Services is a licensed applicator of Azon thermal barrier polymers, specifically the Azon SU 315-14T Structural Thermal Barrier Polymer.

This polymer is designed to work in tandem with high-performance finishes. It creates a strong insulating polymer layer within the extrusion that offers the thermal insulation properties desired while also being structurally sound. This polymer is formulated for rapid curing, allowing Precision Steel Services to process hundreds of feet of aluminum extrusions with ease and meet expedited turnaround times.

The cured thermal barrier polymer, comprised of reactive resin and a polymeric isocyanate, resists fracturing during normal fabrication and exhibits all essential end-use properties dictated by the American Architectural Manufacturers Association (AAMA). By creating a non-metal-to-non-metal connection between components, commercial and residential structures are protected from unwanted heat transfer in both hot and cold environments that can quickly escalate utility costs or create undesirable condensation.

Why OEMs Trust Precision Steel for Thermal Pour & Debridge

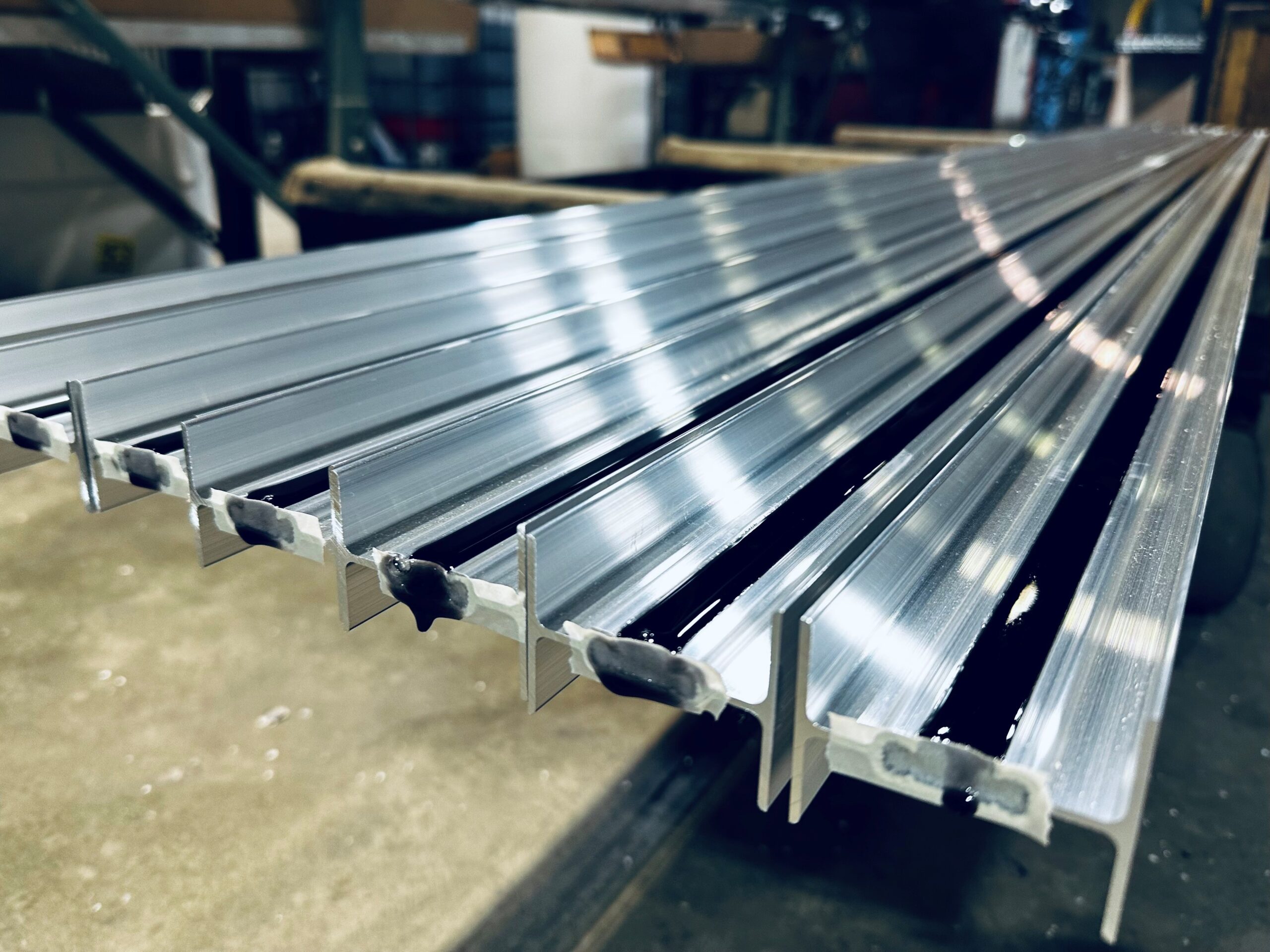

Original equipment manufacturers (OEMs) and other manufacturing companies across the architectural framing, commercial construction, residential window and door systems, and refrigeration equipment choose Precision Steel Services as their thermal pour and debridge company for several reasons. Most notably, the company eliminates the typical constraints and inefficiencies associated with thermal barrier application. These include available powder coating services (necessary to complete before thermal pouring), not typically offered by extruders on smaller orders. Precision Steel does not have any minimum order quantities (MOQs) to qualify for thermal pour and debridge services. This makes it ideal and affordable for manufacturers working with small-run part designs, prototype projects, or even legacy designs.

Integrated Fabrication Capabilities: Reduce Costs & Lead Times

Precision Steel is a full-service sheet metal and extrusion fabricator in addition to being a premium thermal pour and debridge company. The Azon thermal pour line is fully supported by in-house machining services, laser cutting, water jet cutting, powder coating, and even light assembly. This allows its customers to consolidate production into a singular supplier, reducing the need for multiple vendors and further compressing cycle times. Not to mention a drastic reduction in additional freight or handling costs, providing an additional advantage for project-driven industries looking to meet tight deadlines, keeping costs down, and maintaining consistent quality are paramount to success.

Designed for Efficiency in Demanding Applications

No matter if it’s for architectural extrusions that have high standards for thermal performance, commercial storefronts with unique designs, residential window or door systems, or refrigeration equipment with strict tolerances and thermal break requirements, Precision Steel has proven time and time again that it delivers reliable quality, high repeatability, and competitive prices. The results of working with Precision Steel are faster throughput, reduced unit costs, and elevated thermal performance that OEMs have come to trust across every build.

Quotes for Thermal Pour & Debridging Aluminum Extrusions

Precision Steel Services delivers a thermal pour and debridge solution engineered for OEMs that need reliability, flexibility, and speed. By eliminating MOQs, integrating fabrication and finishing steps under one roof, and optimizing every stage of production to maximize performance, they give manufacturers a clear path to reducing unit costs and the ability to meet tighter timelines without sacrificing quality. Precision Steel Services supports diverse industries from architectural and commercial construction to residential products and refrigeration systems, making them a trusted, long-term partner for companies that cannot afford delays or inconsistency in their thermal barrier components.

Find a Supplier Today

" " indicates required fields